| Model | 21 | 21-312 & 21-312V |

| Maximum Capacity | 2,700 lb/hr (1,224 kg/hr) | 3,900 lb/hr (1,69 kg/hr) |

| Maximum Allowable Pressure | 250 psig @ 450°F (17 barg @ 232°C) |

600 psig @ 750°F (41 bar @ 400°C) |

| Maximum Operating Pressure | 250 psig (17 barg) | 600 psig (41 bar) |

| Body Material | ASTM A48 Class 30 Cast Iron |

ASTM A105 Forged Steel |

| Connection Type | Screwed | Screwed Socketweld Flanged |

| Connection Sizes | 1/2″ (15 mm) 3/4″ (20 mm) |

1/2″ (15 mm) 3/4″ (20 mm) 1″ (25 mm) |

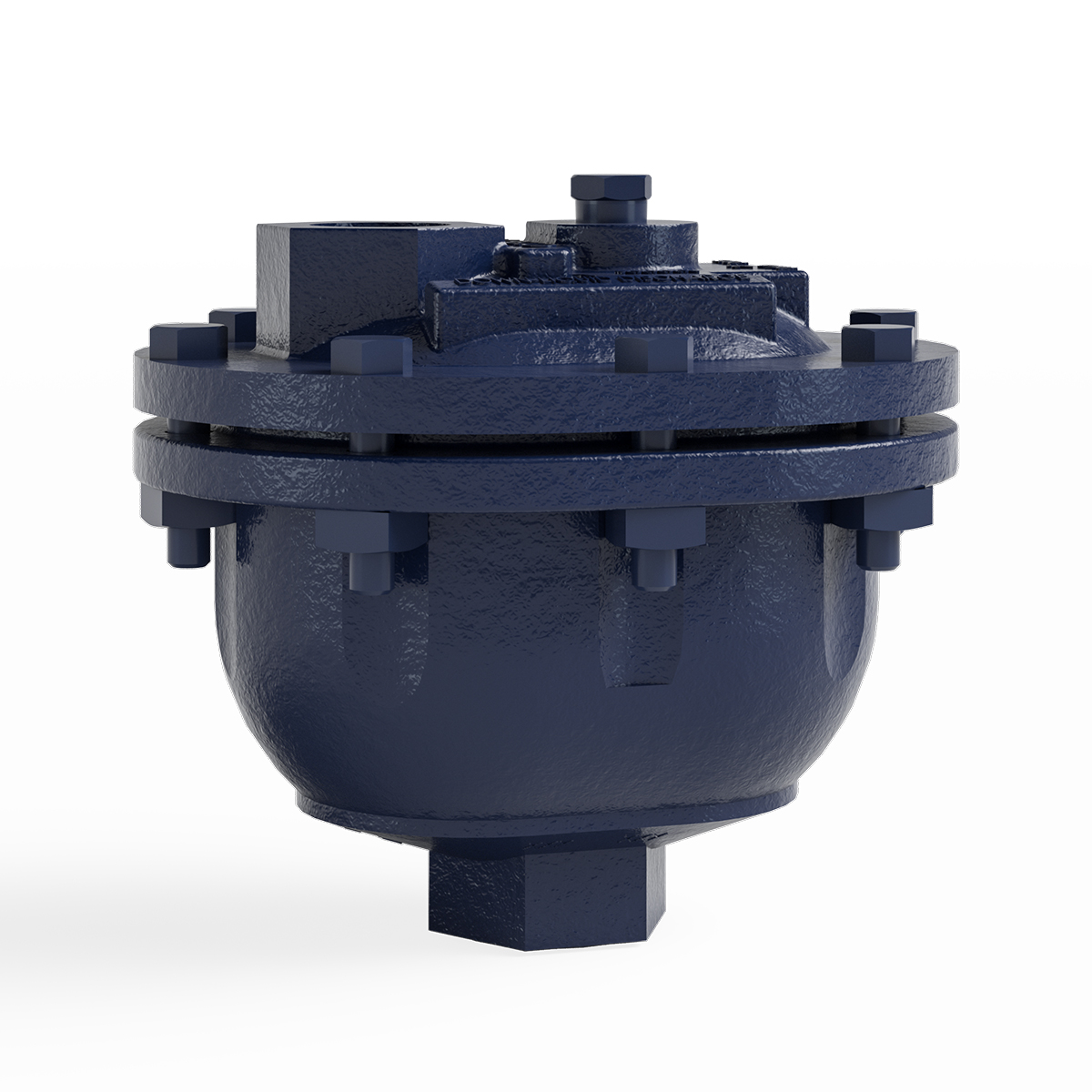

Armstrong’s line of fixed lever, continuous flow or on-off float drain traps includes two basic models available in cast iron and forged steel. The floats are light enough to handle light liquids.

Model 21 is a small, high-quality, economical drain trap for use on drainage jobs where dirt and oil are not encountered. It employs a single lever with a fixed pivot.

Model 21-312 is a forged steel version of the Model 21, with larger float and higher leverage.

CAUTION: Ball float drain traps are not recommended where heavy oil, sludge or considerable dirt are encountered in lines. Under these circumstances, use Armstrong inverted bucket BVSW traps.