As your steam and condensate system partner, Armstrong International can help you improve safety and reduce liability for your hydrocarbon refining and chemical processing plant in ways no one else can.

Call on Armstrong for help in addressing existing safety problems, reducing liability, complying with government standards, and preventing critical or dangerous issues, such as: water hammer, superheated steam leaks, burns, ice formation, low visibility due to excess steam, and more.

Products and Systems for HPI/CPI

Our experts know what to look for, and what to do, whenever we find an existing problem, potential issue, or opportunity for improvement.

As your thermal utility partner, Armstrong gives you access to more than a century of knowledge and experience. We can help you establish customized standards and best practices to comply with stringent environmental requirements and address critical safety issues throughout your facilities, anywhere in the world.

The Causes & Effects of Water Hammer

Dangers of Water Hammer

Custom-Engineered Piping Solutions, Complete With Steam Traps, Control Valves, Trap Valve Stations and Condensate Removal Equipment

Armstrong’s experienced specialists are skilled, trained and ready to help you: monitor steam traps and steam quality; ensure that steam traps are properly sized, selected and in working order; and deaerate and maintain condensate at appropriately high temperatures.

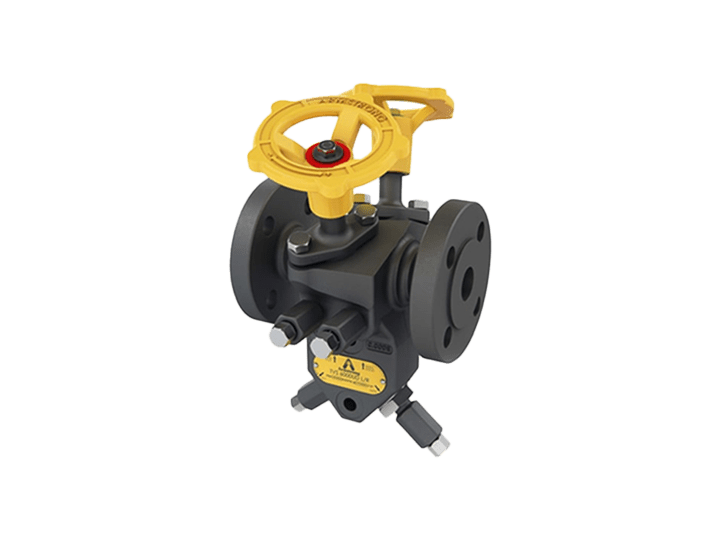

State-of-the-Art Thermal Utility System Management

Armstrong gives you deep, real-time insight into your thermal utilities with this fully integrated monitoring and documentation platform. By delivering the right information to the right people at the right time, SAGE® keeps you informed, 24 hours a day. If an issue arises, SAGE® alerts you instantly so you can take immediate action.

Cutting-Edge Technology for Smart Trap Surveys

Armstrong eliminates human error and makes testing steam traps as simple as pressing a button with our automatic testing device, SAGE UMT®. Using our wireless, handheld steam trap tester, any steam trap technician can survey your trap population quickly and accurately, on a regular basis.

Sustainable, Proactive Steam Trap Management Services

Whether your company has 10 steam traps or 10,000, in one location or facilities all over the world, Armstrong can show you how to manage your steam system better than anyone in the world. Our holistic approach considers your entire steam system, as well as the unique requirements of your facilities and industry as we implement a custom-designed program to increase reliability, efficiency and safety.

Wireless Steam System Monitoring for Critical Traps or Your Entire Steam Trap Population

Real-time insight and instantaneous notifications of any problems enables you to repair or replace failed traps before they create serious steam quality issues.

Flow Meters That Accurately Measure Energy Consumption

Armstrong’s advanced flow measurement technology delivers world-class accuracy and reliability for steam, water or gas. We offer a full line of differential pressure flow elements and vortex meters, as well as VERIS Accelabar®—our patented meter that doesn’t require any straight pipe lengths for installation.

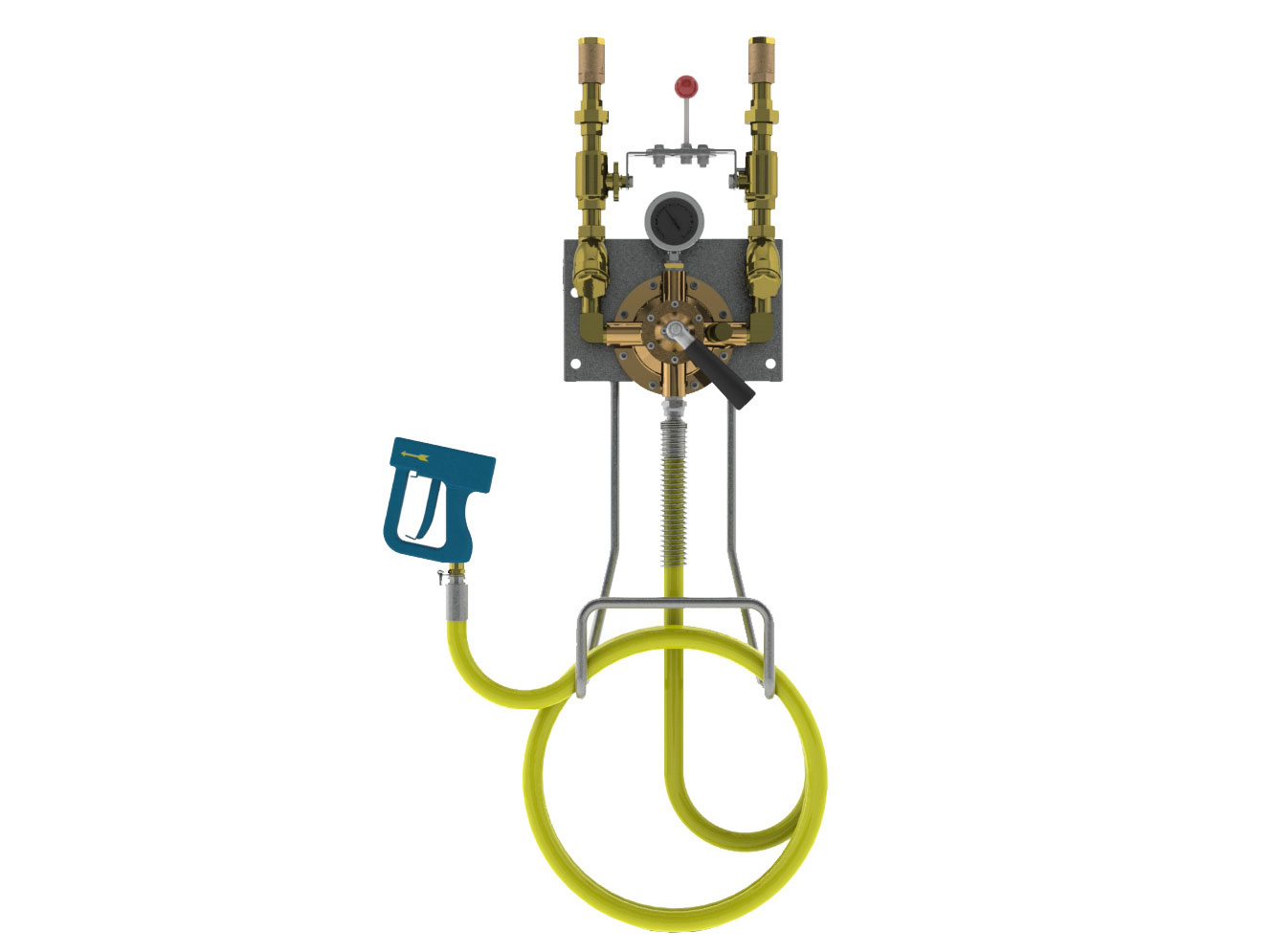

Hose Stations That Will Not Pass Live Steam

Armstrong hose stations improve efficiency and reduce risk when mixing steam and water at the point of use for wash-down. Our hose stations will not pass live steam, even in the event of a significant cold water pressure reduction, complete failure of the cold water supply, or failure of its primary operating component.

Industrial Hot Water Solutions Brochure