Le soluzioni di Armstrong International sono progettate su misura per facilitare la manutenzione, migliorare l’affidabilità e le prestazioni e velocizzare gli aggiornamenti e le modifiche.

Rivolgetevi ad Armstrong per le best practice in materia di tubazioni, pensate per soddisfare i requisiti specifici di ogni unità, di ogni raffineria o dell’intera azienda, in tutto il mondo. In qualità di leader mondiale nell’ottimizzazione dei sistemi vapore e condensa, i nostri specialisti sono pronti ad aiutarvi a risolvere i problemi del vostro impianto di raffinazione di idrocarburi o di lavorazione di prodotti chimici.

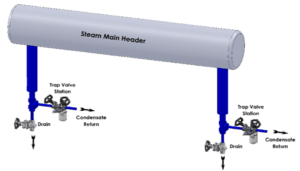

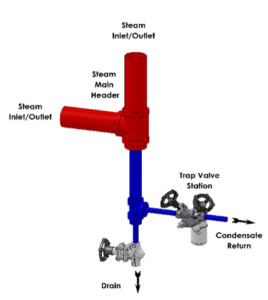

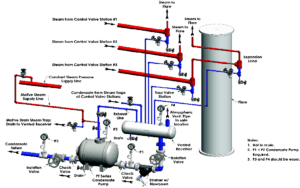

Punti di scarico

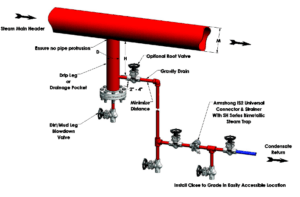

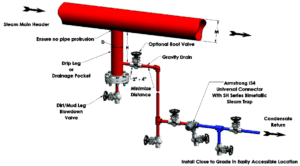

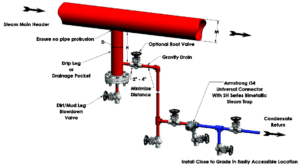

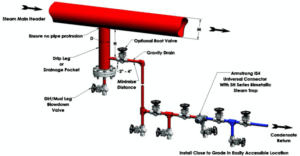

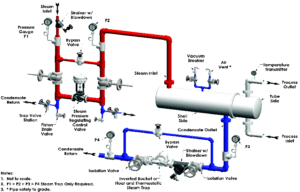

Steam Trap Location Points - Steam Main Header

Installare punti di scarico della condensa con scaricatori di condensa. Vapore saturo: ogni 150-300 piedi (25-50 m). Vapore surriscaldato: ogni 300-500 piedi (50-75 m)

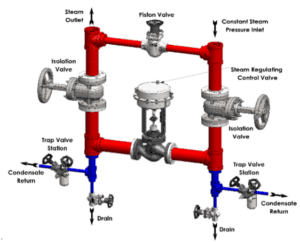

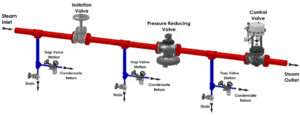

Steam Valve Station Drainage

Installare gli scaricatori di condensa a valle di valvole manuali normalmente chiuse, valvole di riduzione della pressione e valvole di controllo.

Steam Trap Location Points - Steam Main Header

Installare punti di scarico della condensa con scaricatori di condensa in fondo a qualsiasi sollevamento verticale indipendentemente dalla direzione del flusso di vapore.

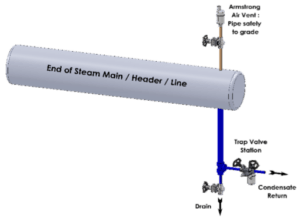

Steam Trap Location Points – End of Steam Main / Header / Line

L’installazione di sfiati d’aria all’estremità della sede principale impedirà che l’aria venga scaricata nella testata, in particolare durante l’avviamento.

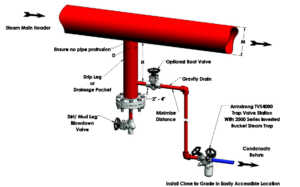

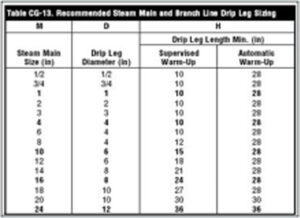

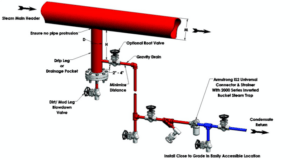

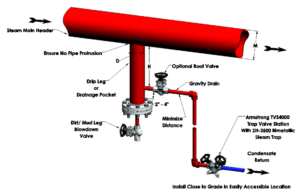

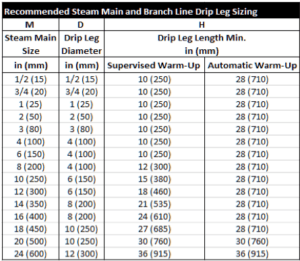

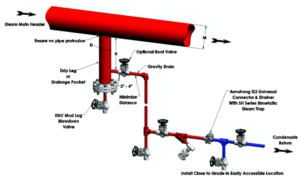

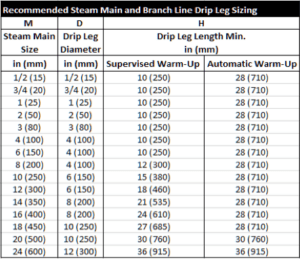

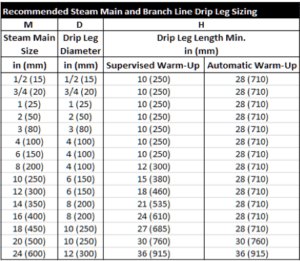

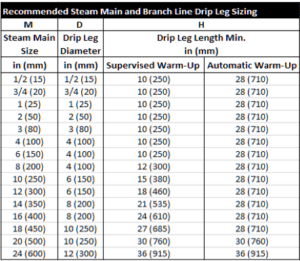

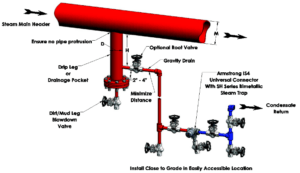

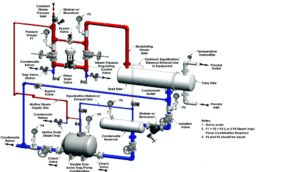

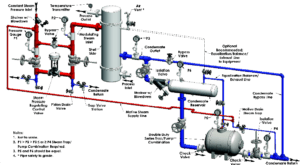

Tasche di drenaggio

Steam Main Header Drip Trap – Saturated (≤ 650 psig /45 barg)

Steam Main Header Drip Trap – Saturated (≤ 650 psig /45 barg)

Steam Main Header Drip Trap – Saturated (≤ 650 psig /45 barg)

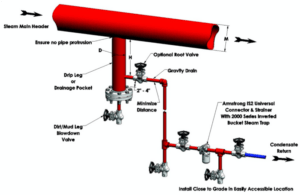

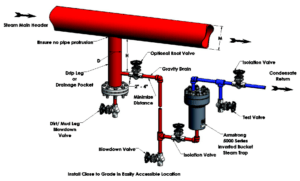

Steam Main Header Drip Trap – Superheated (≤ 650 psig & 600°F / 45 barg & 315°C)

Steam Main Header Drip Trap – Superheated (≤ 650 psig & 600°F / 45 barg & 315°C)

Steam Main Header Drip Trap – Superheated (≤ 650 psig & 600°F / 45 barg & 315°C)

Steam Main Header Drip Trap – Saturated (650 ≤ 1,800 psig / 45 ≤ 124 barg )

Steam Main Header Drip Trap - Superheated Single Block and Bleed (650 ≤ 1,245 psig @ 900°F / 45 ≤ 86 barg @ 482°C)

Steam Main Header Drip Trap – Double Block and Bleed (650 ≤ 1,245 psig @ 900 °F / 45 ≤ 86 barg @ 482°C)

Steam Main Header Drip Trap – Superheated, Double Block and Bleed (650 ≤ 1,245 psig @ 900 °F/45 ≤ 86 barg @ 482°C)

Steam Main Header Drip Trap – Superheated, Double Block and Bleed (650 ≤ 1,245 psig @ 900 °F / 45 ≤ 86 barg @ 482°C)

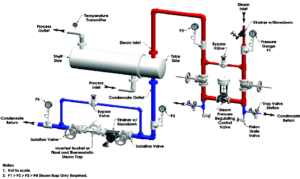

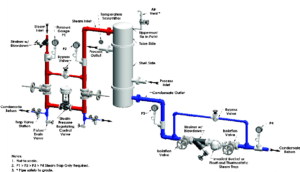

Riscaldatori di processo

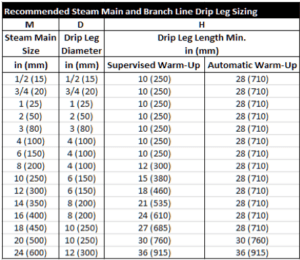

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Shell Side (≤ 650 psig /45 barg) Constant Positive Differential Pressure (Non-Stall)

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Shell Side (≤ 200 psig /14 barg) Modulating Differential Pressure (Stall) – Closed System

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Tube Side (≤ 650 psig /45 barg) Constant Positive Differential Pressure (Non-Stall)

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Tube Side (≤ 200 psig / 14 barg) Modulating Differential Pressure (Stall) – Closed System

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Tube Side (≤ 650 psig / 45 barg) Constant Positive Differential Pressure (Non-Stall)

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Shell Side (≤ 200 psig /14 barg) Modulating Differential Pressure (Stall) – Closed System

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Tube Side (≤ 650 psig / 45 barg) Constant Positive Differential Pressure (Non-Stall)

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Tube Side (≤ 200 psig / 14 barg) Modulating Differential Pressure (Stall) – Closed System

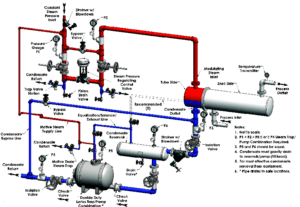

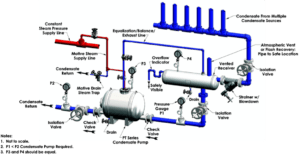

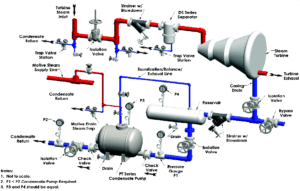

Sistemi aperti

Condensate from Multiple Sources – Saturated (≤ 150 psig / 10 barg) Negative Differential Pressure – Open System

Condensing Steam Turbine – Saturated (≤ 150 psig / 10 barg) Negative Differential Pressure – Closed System

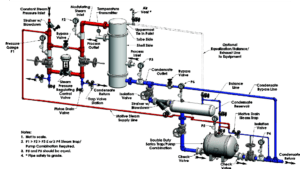

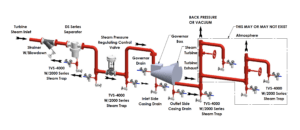

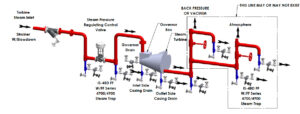

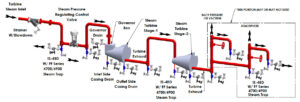

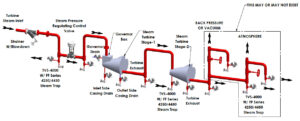

Turbine

Steam Turbine Saturated – Single Stage Positive Differential Pressure (≤ 650 Psig/ 45 Bar Saturated)

Steam Turbine Saturated – Multiple Stages Positive Differential Pressure (≤ 650 Psig/ 45 Bar Saturated)

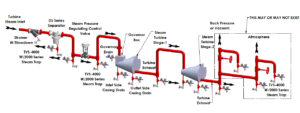

Steam Turbine – Single Stage Positive Differential Pressure Low Pressure (≤ 450 Psig/ 31 Bar Superheated)

Steam Turbine – Single Stage Positive Differential Pressure High Pressure (≤ 1245 Psig/ 86 Bar Superheated)

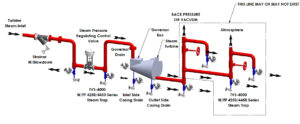

Steam Turbine Superheated – Multiple Stages Positive Differential Pressure Low Pressure (≤ 450 Psig/ 31 Bar Superheated)

Steam Turbine – Multiple Stages Positive High Pressure (450 Psig ≤ 1245 Psig/ 31 Bar ≤ 86 Bar Superheated)

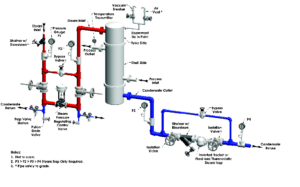

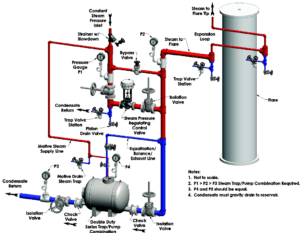

Torce

Flare Systems – Single Steam Supply (≤ 200 psig / 14 barg) Closed System

Flare Systems – Multiple Steam Supplies (≤ 150 psig / 10 barg) Open System

Serbatoi di accumulo

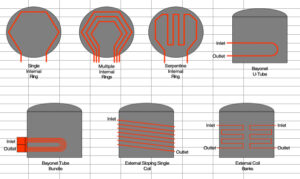

Storage Tank Coil Types

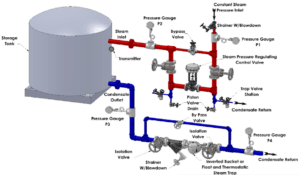

Storage Tank – Saturated – Single Steam Supply Constant Pressure (Non-Stall) (0 ≤ 650 psig / 0 ≤ 45 barg)

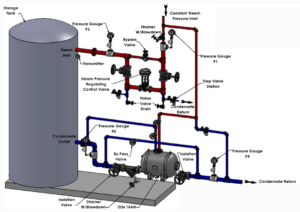

Storage Tank – Saturated – Single Steam Supply Modulating Pressure (Stall) (0 ≤ 200 psig / 0 ≤ 14 barg)

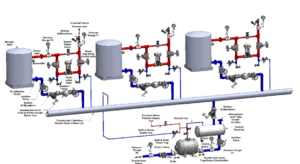

Multiple Storage Tanks – Saturated – Single Steam Supply Constant Pressure (≤ 150 psig /10 barg)

Tracciatura

Steam Tracing Systems