Les solutions sur mesure d’Armstrong International facilitent l’entretien, améliorent la fiabilité et les performances des réseaux, et accélèrent les modernisations et remplacements.

Faites appel aux experts dʼArmstrong pour connaître les bonnes pratiques de raccordement en fonction des besoins spécifiques dʼun service, dʼune raffinerie ou de lʼensemble de lʼentreprise, partout dans le monde. En tant que leader mondial de lʼoptimisation des réseaux vapeur et condensat, nous mettrons notre expertise à votre service pour résoudre les problèmes de votre usine de traitement dʼhydrocarbures et de produits chimiques.

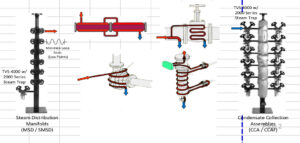

Points de purge

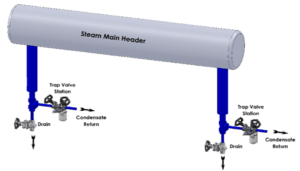

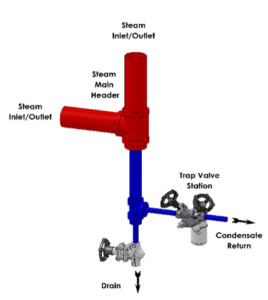

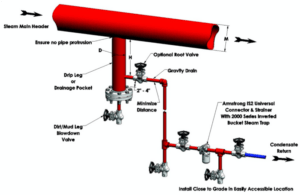

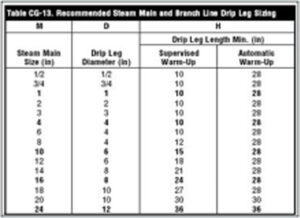

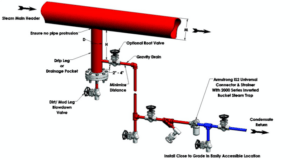

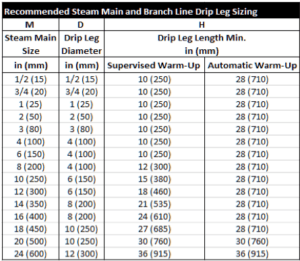

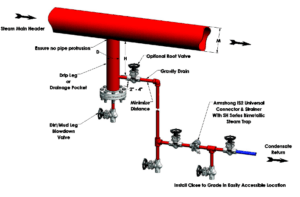

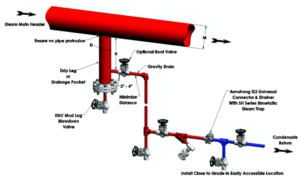

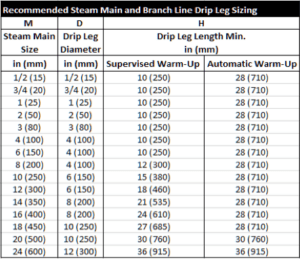

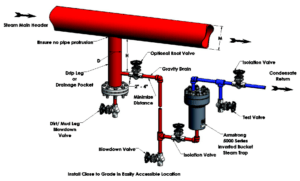

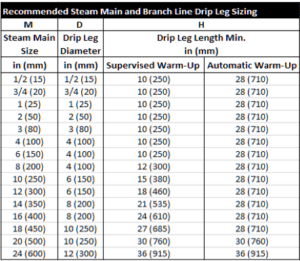

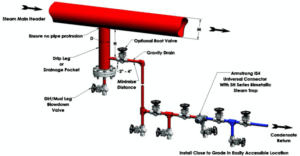

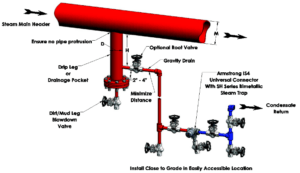

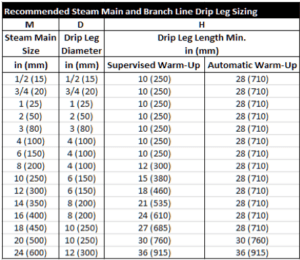

Steam Trap Location Points - Steam Main Header

Installez des points de purge des condensats avec les purgeurs. Vapeur saturée : tous les 25–50 m (150–300 pieds). Vapeur surchauffée : tous les 50–75 m (300–500 pieds).

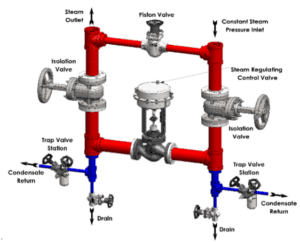

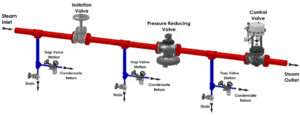

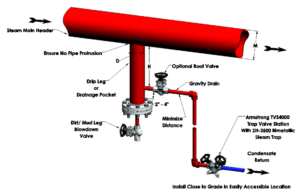

Steam Valve Station Drainage

Installez les purgeurs avant les régulateurs de pression, vannes de régulation et vannes manuelles normalement fermés.

Steam Trap Location Points - Steam Main Header

Installez des points de purge des condensats avec les purgeurs en bas de chaque refoulement vertical, quel que soit le sens de circulation de la vapeur.

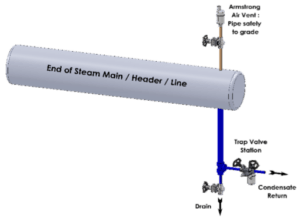

Steam Trap Location Points – End of Steam Main / Header / Line

Lʼinstallation dʼévents en fin de conduite empêche lʼemprisonnement de lʼair dans le collecteur de vapeur, en particulier lors des démarrages.

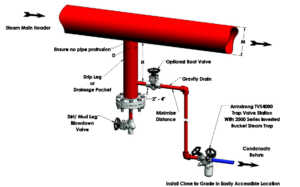

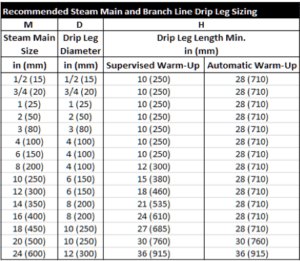

Pots de purge

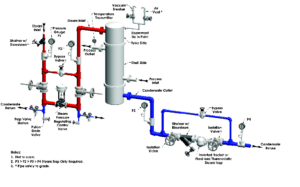

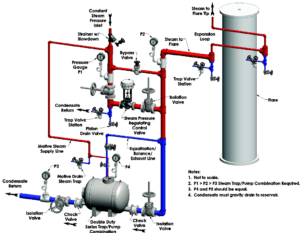

Steam Main Header Drip Trap – Saturated (≤ 650 psig /45 barg)

Steam Main Header Drip Trap – Saturated (≤ 650 psig /45 barg)

Steam Main Header Drip Trap – Saturated (≤ 650 psig /45 barg)

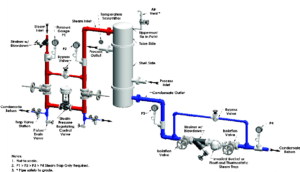

Steam Main Header Drip Trap – Superheated (≤ 650 psig & 600°F / 45 barg & 315°C)

Steam Main Header Drip Trap – Superheated (≤ 650 psig & 600°F / 45 barg & 315°C)

Steam Main Header Drip Trap – Superheated (≤ 650 psig & 600°F / 45 barg & 315°C)

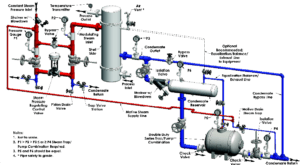

Steam Main Header Drip Trap – Saturated (650 ≤ 1,800 psig / 45 ≤ 124 barg )

Steam Main Header Drip Trap - Superheated Single Block and Bleed (650 ≤ 1,245 psig @ 900°F / 45 ≤ 86 barg @ 482°C)

Steam Main Header Drip Trap – Double Block and Bleed (650 ≤ 1,245 psig @ 900 °F / 45 ≤ 86 barg @ 482°C)

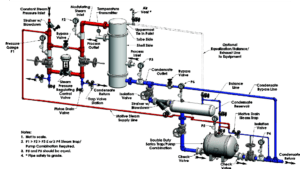

Steam Main Header Drip Trap – Superheated, Double Block and Bleed (650 ≤ 1,245 psig @ 900 °F/45 ≤ 86 barg @ 482°C)

Steam Main Header Drip Trap – Superheated, Double Block and Bleed (650 ≤ 1,245 psig @ 900 °F / 45 ≤ 86 barg @ 482°C)

Réchauffeurs pour process

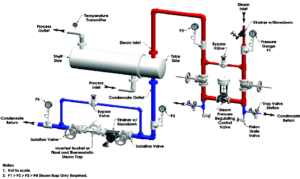

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Shell Side (≤ 650 psig /45 barg) Constant Positive Differential Pressure (Non-Stall)

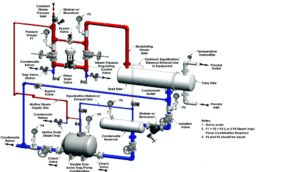

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Shell Side (≤ 200 psig /14 barg) Modulating Differential Pressure (Stall) – Closed System

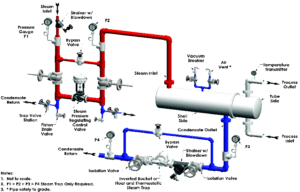

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Tube Side (≤ 650 psig /45 barg) Constant Positive Differential Pressure (Non-Stall)

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Tube Side (≤ 200 psig / 14 barg) Modulating Differential Pressure (Stall) – Closed System

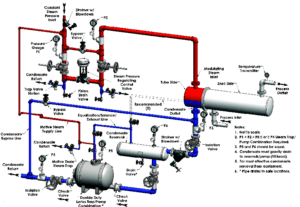

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Tube Side (≤ 650 psig / 45 barg) Constant Positive Differential Pressure (Non-Stall)

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Shell Side (≤ 200 psig /14 barg) Modulating Differential Pressure (Stall) – Closed System

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Tube Side (≤ 650 psig / 45 barg) Constant Positive Differential Pressure (Non-Stall)

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Tube Side (≤ 200 psig / 14 barg) Modulating Differential Pressure (Stall) – Closed System

Systèmes ouverts

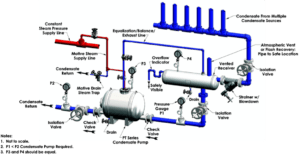

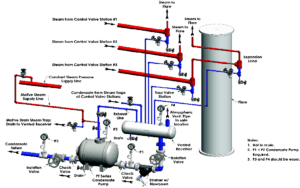

Condensate from Multiple Sources – Saturated (≤ 150 psig / 10 barg) Negative Differential Pressure – Open System

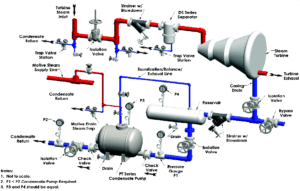

Condensing Steam Turbine – Saturated (≤ 150 psig / 10 barg) Negative Differential Pressure – Closed System

Turbines

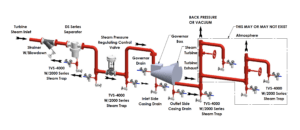

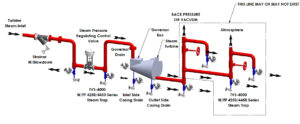

Steam Turbine Saturated – Single Stage Positive Differential Pressure (≤ 650 Psig/ 45 Bar Saturated)

Steam Turbine Saturated – Multiple Stages Positive Differential Pressure (≤ 650 Psig/ 45 Bar Saturated)

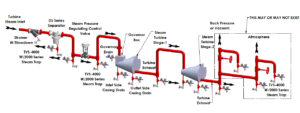

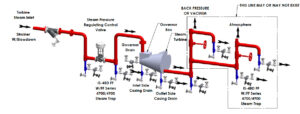

Steam Turbine – Single Stage Positive Differential Pressure Low Pressure (≤ 450 Psig/ 31 Bar Superheated)

Steam Turbine – Single Stage Positive Differential Pressure High Pressure (≤ 1245 Psig/ 86 Bar Superheated)

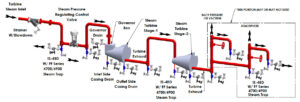

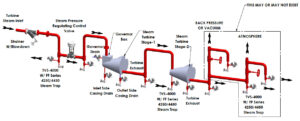

Steam Turbine Superheated – Multiple Stages Positive Differential Pressure Low Pressure (≤ 450 Psig/ 31 Bar Superheated)

Steam Turbine – Multiple Stages Positive High Pressure (450 Psig ≤ 1245 Psig/ 31 Bar ≤ 86 Bar Superheated)

Torchères

Flare Systems – Single Steam Supply (≤ 200 psig / 14 barg) Closed System

Flare Systems – Multiple Steam Supplies (≤ 150 psig / 10 barg) Open System

Réservoirs de stockage

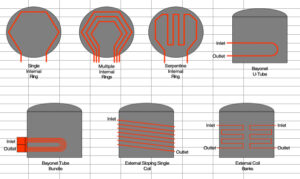

Storage Tank Coil Types

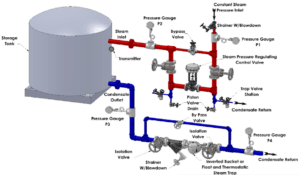

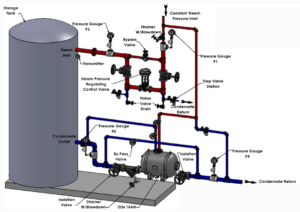

Storage Tank – Saturated – Single Steam Supply Constant Pressure (Non-Stall) (0 ≤ 650 psig / 0 ≤ 45 barg)

Storage Tank – Saturated – Single Steam Supply Modulating Pressure (Stall) (0 ≤ 200 psig / 0 ≤ 14 barg)

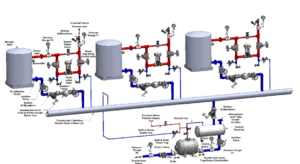

Multiple Storage Tanks – Saturated – Single Steam Supply Constant Pressure (≤ 150 psig /10 barg)

Traçage

Steam Tracing Systems