De oplossingen van Armstrong International zijn op maat gemaakt voor eenvoudiger onderhoud, verbeterde betrouwbaarheid en prestaties, en snellere updates en wijzigingen.

Schakel Armstrong in voor deskundige best practices voor leidingwerk, die voldoen aan de specifieke vereisten van elke unit, elke raffinaderij of uw gehele bedrijf, op locaties overal ter wereld. Als wereldleider op het gebied van de optimalisatie van stoom- en condensaatsystemen kunnen onze specialisten u helpen bij de problemen waarmee u wordt geconfronteerd met uw installatie voor de raffinage van koolwaterstoffen of chemische verwerkingsinstallatie.

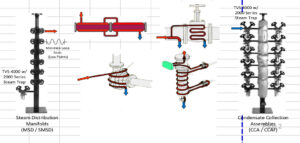

Afvoerpunten

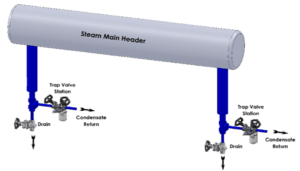

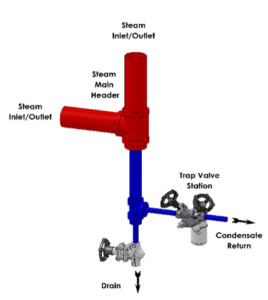

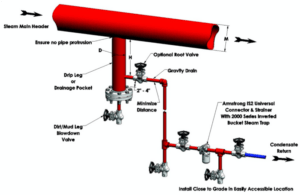

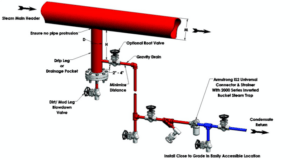

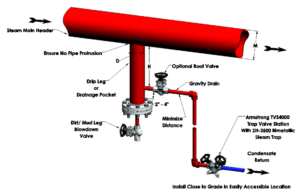

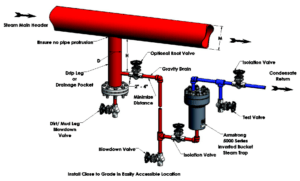

Steam Trap Location Points - Steam Main Header

Installeer condensaatafvoerpunten met condenspotten. Verzadigde stoom: elke 25 tot 50 m. Oververhitte stoom: elke 50 tot 75 m

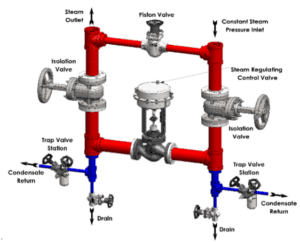

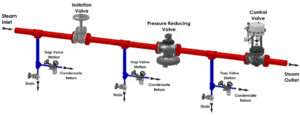

Steam Valve Station Drainage

Installeer condenspotten vóór normaal gesloten handbediende kleppen, drukreduceerkleppen en regelkleppen.

Steam Trap Location Points - Steam Main Header

Installeer condensaatafvoerpunten met condenspotten onderaan elke verticale opvoer, ongeacht de stroomrichting van de stoom.

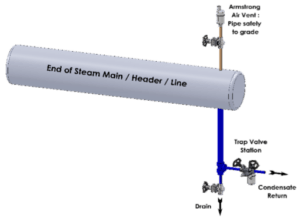

Steam Trap Location Points – End of Steam Main / Header / Line

Met de installatie van ontluchters aan het einde van de toevoerleidingen voorkomt u dat lucht in het verdeelstuk opgesloten raakt, vooral tijdens de aanloopperioden.

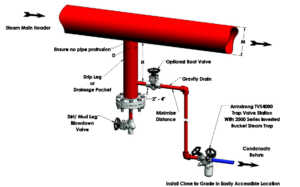

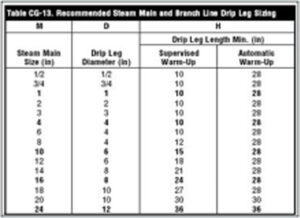

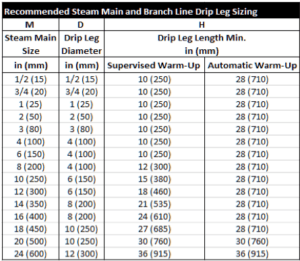

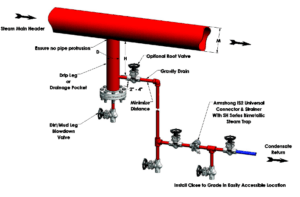

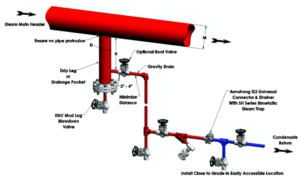

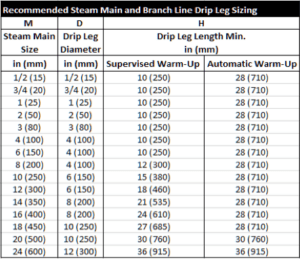

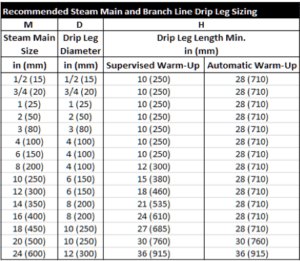

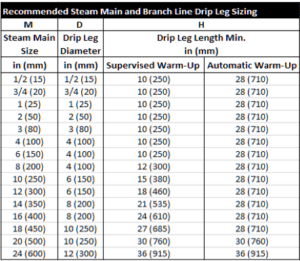

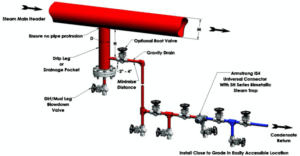

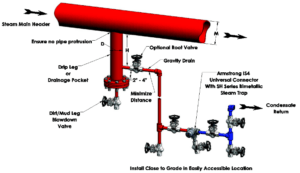

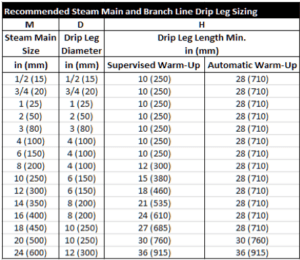

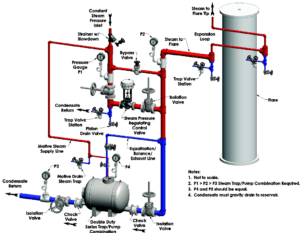

Zakpijpen

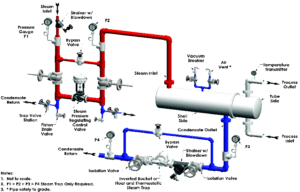

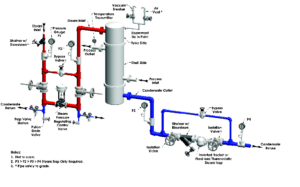

Steam Main Header Drip Trap – Saturated (≤ 650 psig /45 barg)

Steam Main Header Drip Trap – Saturated (≤ 650 psig /45 barg)

Steam Main Header Drip Trap – Saturated (≤ 650 psig /45 barg)

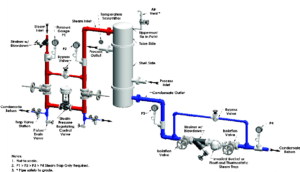

Steam Main Header Drip Trap – Superheated (≤ 650 psig & 600°F / 45 barg & 315°C)

Steam Main Header Drip Trap – Superheated (≤ 650 psig & 600°F / 45 barg & 315°C)

Steam Main Header Drip Trap – Superheated (≤ 650 psig & 600°F / 45 barg & 315°C)

Steam Main Header Drip Trap – Saturated (650 ≤ 1,800 psig / 45 ≤ 124 barg )

Steam Main Header Drip Trap - Superheated Single Block and Bleed (650 ≤ 1,245 psig @ 900°F / 45 ≤ 86 barg @ 482°C)

Steam Main Header Drip Trap – Double Block and Bleed (650 ≤ 1,245 psig @ 900 °F / 45 ≤ 86 barg @ 482°C)

Steam Main Header Drip Trap – Superheated, Double Block and Bleed (650 ≤ 1,245 psig @ 900 °F/45 ≤ 86 barg @ 482°C)

Steam Main Header Drip Trap – Superheated, Double Block and Bleed (650 ≤ 1,245 psig @ 900 °F / 45 ≤ 86 barg @ 482°C)

Procesverwarmingen

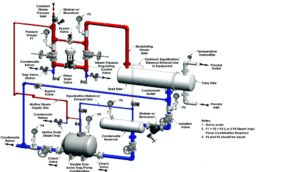

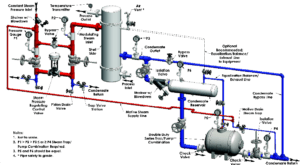

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Shell Side (≤ 650 psig /45 barg) Constant Positive Differential Pressure (Non-Stall)

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Shell Side (≤ 200 psig /14 barg) Modulating Differential Pressure (Stall) – Closed System

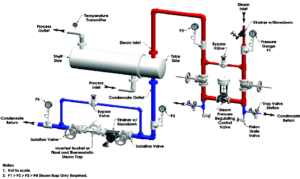

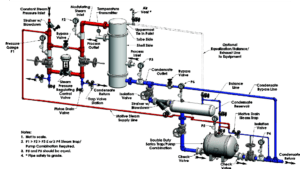

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Tube Side (≤ 650 psig /45 barg) Constant Positive Differential Pressure (Non-Stall)

Shell & Tube Heat Exchanger – Horizontal – Saturated Steam on Tube Side (≤ 200 psig / 14 barg) Modulating Differential Pressure (Stall) – Closed System

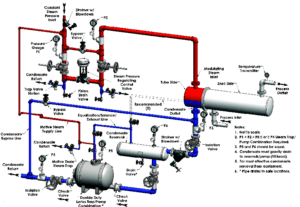

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Tube Side (≤ 650 psig / 45 barg) Constant Positive Differential Pressure (Non-Stall)

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Shell Side (≤ 200 psig /14 barg) Modulating Differential Pressure (Stall) – Closed System

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Tube Side (≤ 650 psig / 45 barg) Constant Positive Differential Pressure (Non-Stall)

Shell & Tube Heat Exchanger – Vertical – Saturated Steam on Tube Side (≤ 200 psig / 14 barg) Modulating Differential Pressure (Stall) – Closed System

Open systemen

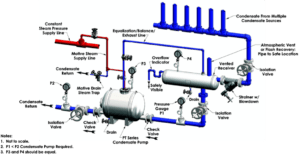

Condensate from Multiple Sources – Saturated (≤ 150 psig / 10 barg) Negative Differential Pressure – Open System

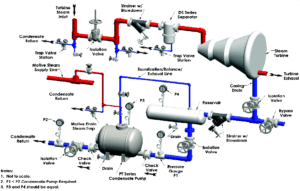

Condensing Steam Turbine – Saturated (≤ 150 psig / 10 barg) Negative Differential Pressure – Closed System

Turbines

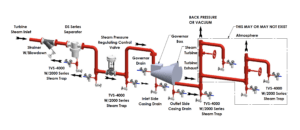

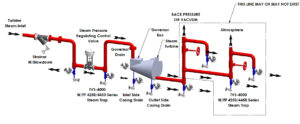

Steam Turbine Saturated – Single Stage Positive Differential Pressure (≤ 650 Psig/ 45 Bar Saturated)

Steam Turbine Saturated – Multiple Stages Positive Differential Pressure (≤ 650 Psig/ 45 Bar Saturated)

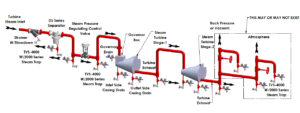

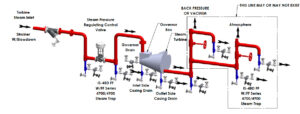

Steam Turbine – Single Stage Positive Differential Pressure Low Pressure (≤ 450 Psig/ 31 Bar Superheated)

Steam Turbine – Single Stage Positive Differential Pressure High Pressure (≤ 1245 Psig/ 86 Bar Superheated)

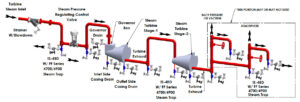

Steam Turbine Superheated – Multiple Stages Positive Differential Pressure Low Pressure (≤ 450 Psig/ 31 Bar Superheated)

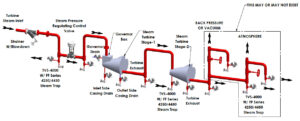

Steam Turbine – Multiple Stages Positive High Pressure (450 Psig ≤ 1245 Psig/ 31 Bar ≤ 86 Bar Superheated)

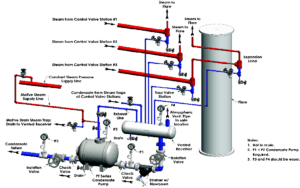

Flares

Flare Systems – Single Steam Supply (≤ 200 psig / 14 barg) Closed System

Flare Systems – Multiple Steam Supplies (≤ 150 psig / 10 barg) Open System

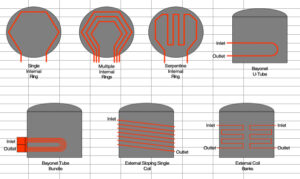

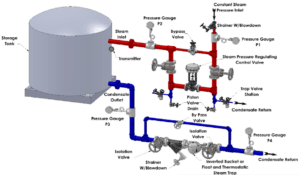

Opslagtanks

Storage Tank Coil Types

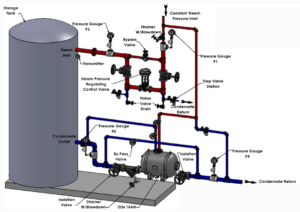

Storage Tank – Saturated – Single Steam Supply Constant Pressure (Non-Stall) (0 ≤ 650 psig / 0 ≤ 45 barg)

Storage Tank – Saturated – Single Steam Supply Modulating Pressure (Stall) (0 ≤ 200 psig / 0 ≤ 14 barg)

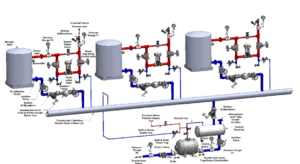

Multiple Storage Tanks – Saturated – Single Steam Supply Constant Pressure (≤ 150 psig /10 barg)

Opsporing

Steam Tracing Systems